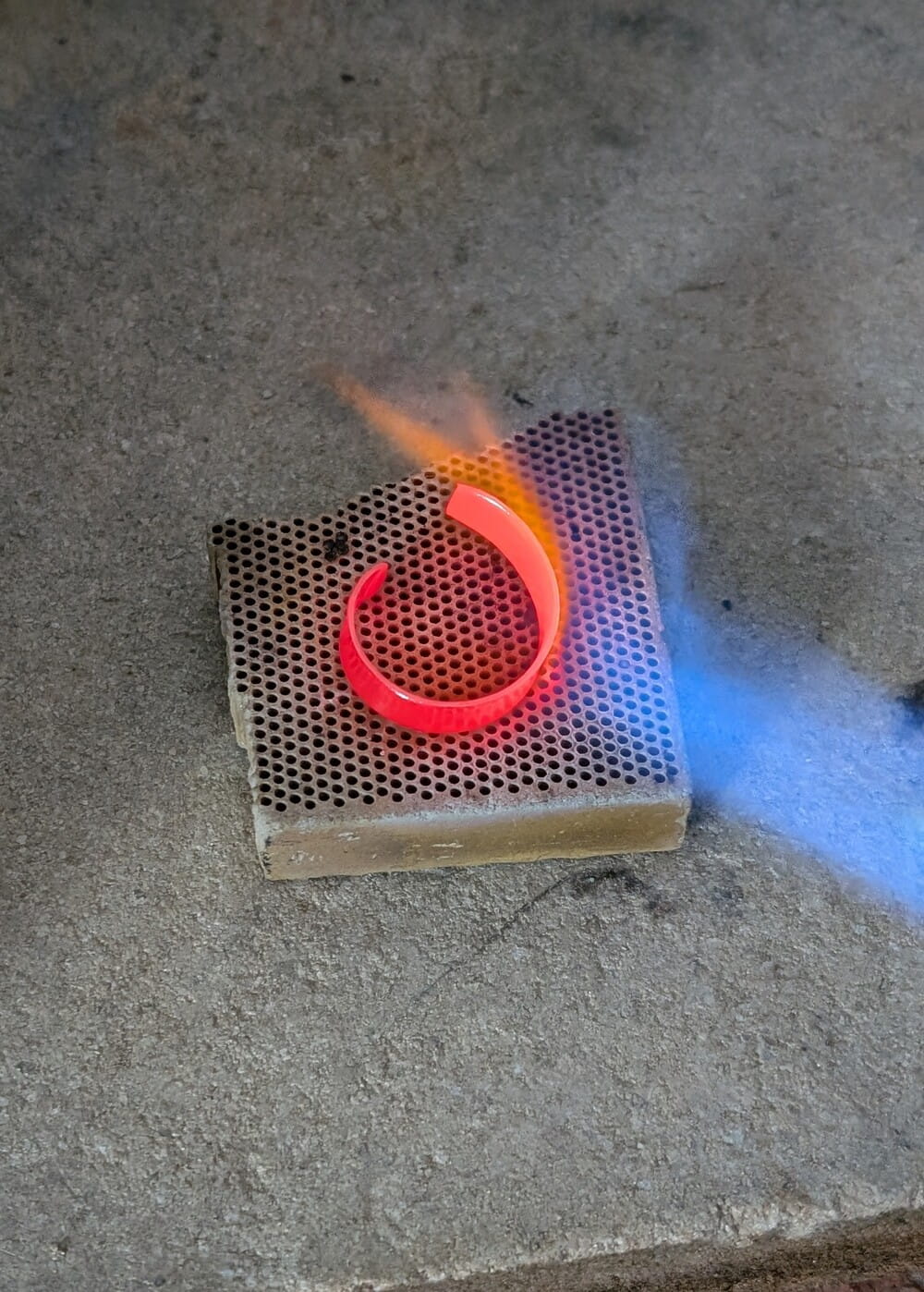

Annealing is an essential process in goldsmithing that allows metals like gold, silver, and platinum to be reshaped after bending or forging. When these metals are worked, they harden, making it difficult to continue shaping them. During annealing, the material is heated until it glows red or orange and then rapidly cooled, usually in water. This process softens the metal again, making it malleable for further work.

Annealing helps reduce internal stress in the metal, preventing cracks or breaks during subsequent shaping. It also makes soldering easier and allows for better surface texture and finishing, giving the piece its desired look. Each metal has its own optimal temperature for annealing, with gold typically being heated to between 430°C and 595°C (800°F and 1,100°F).

For safety, heat-resistant gloves and goggles should always be worn, and work should be done in a well-ventilated area. Caution should also be taken when quenching the metal to avoid burns.

Please click on Additional information to find a list of needed tools and further information on this tutorial.