Welding plays a pivotal role in the art of jewelry creation, offering a distinctive method of joining precious metalswithout the need for soldering. This technique utilizes flux, which facilitates the fusion of two metals by creating an environment that prevents oxidation during the heating process. When applied, the metals are placed directly on top of each other, and as heat is gradually introduced, the surface of the materials begins to liquefy. This allows the two pieces to bond seamlessly, creating a strong and durable connection.

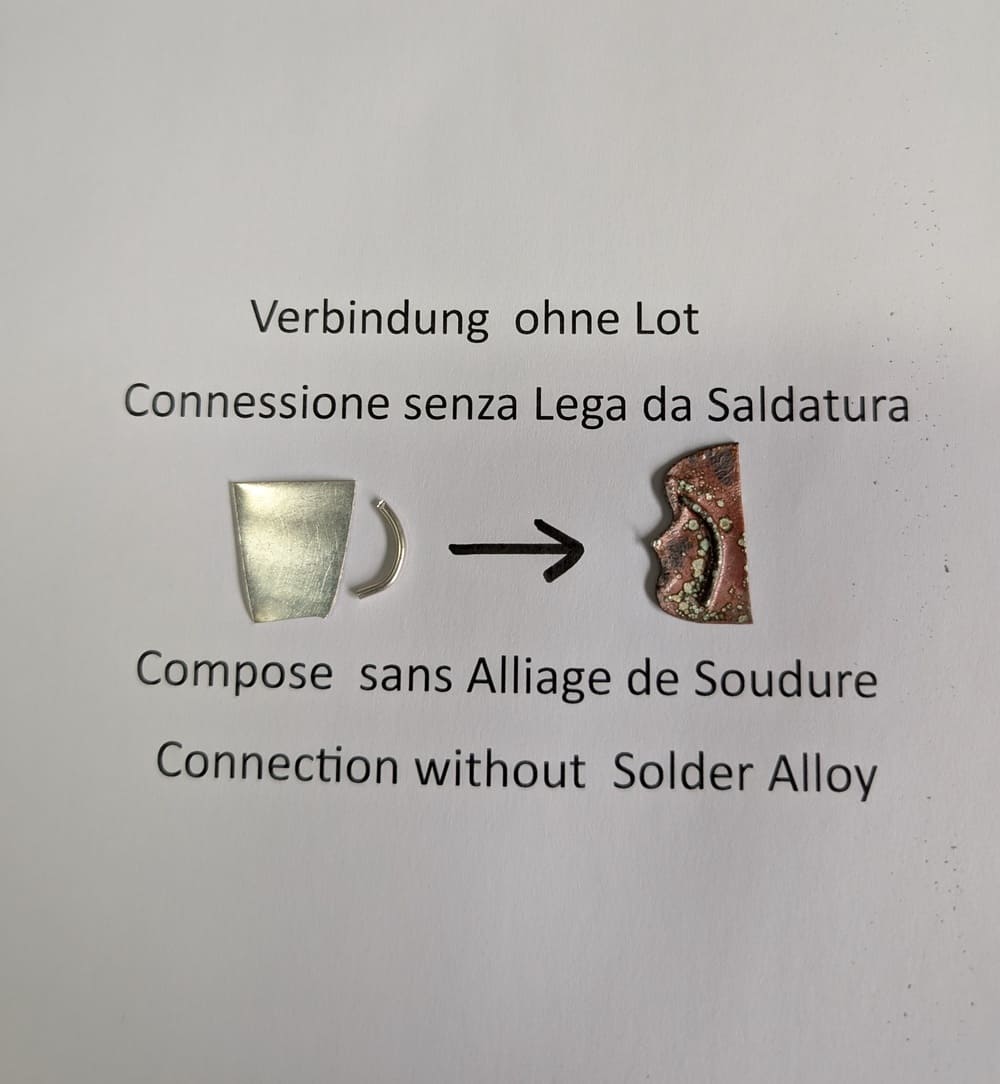

Unlike traditional soldering, welding does not require any filler material. The metals themselves are melted at their surfaces to form a secure attachment, which can be particularly advantageous when working with delicate or precious materials, such as fine gold or fine silver. This method not only preserves the integrity of the metals but also allows for the creation of intricate designs with a minimal risk of distortion or unsightly seams. However, a certain level of skill and precision is required, as the heat must be carefully controlled to ensure that the pieces bond properly without causing excessive deformation.

One of the most exciting aspects of welding is its versatility. The technique is not limited to just one type of metal; in fact, it can be successfully applied between different metals. For example, fine gold can be welded to fine silver, opening up a wide range of creative possibilities for jewelers. The ability to combine different materials in a single piece allows for the exploration of contrasting colors and textures, adding depth and visual interest to the final design.

While welding can be considered somewhat experimental, its use in jewelry making has become increasingly popular due to its ability to create seamless, almost invisible joints. This method is particularly valuable in high-end jewelry creation, where the focus is on maintaining the purity of the metals and achieving a flawless finish. As with any intricate craft, mastery of the welding process requires practice, patience, and a deep understanding of how different metals respond to heat. However, when executed correctly, it can yield stunning results that elevate a jewelry piece to the next level of craftsmanship.

Please click on Additional information to find a list of needed tools and further information on this tutorial.