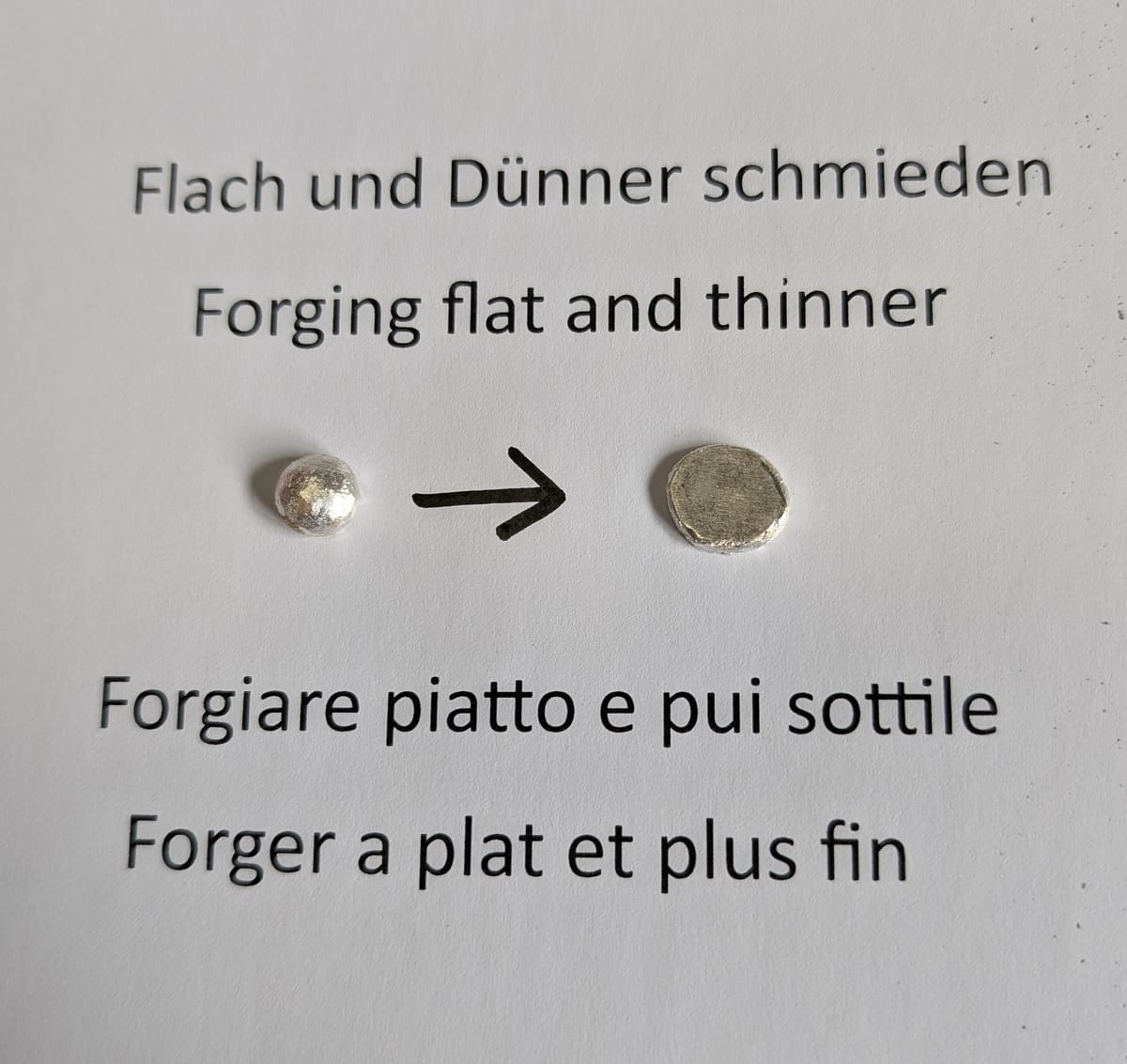

Forging metals to become thinner and flatter is a key technique in goldsmithing, allowing jewelers to shape precious metals like gold, silver, and platinum into intricate designs. This process involves applying controlled pressure to the metal, causing it to expand and become thinner, which is essential for achieving specific shapes and sizes in jewelry.

As the metal is hammered or pressed, it hardens, gaining strength. To prevent brittleness, the material must be annealed—heated to a specific temperature to soften it again. This cycle of forging and annealing is repeated until the desired thickness and form are achieved. The higher the purity of the metal, such as fine gold or sterling silver, the easier the forging process becomes. In contrast, lower-purity metals like 8-carat gold are harder and more brittle, requiring more care during forging.

Beyond shaping, forging also strengthens the metal, making it more durable, which is crucial for creating long-lasting jewelry. Whether for delicate filigree, intricate wirework, or sturdy bands, forging offers flexibility and precision in jewelry making. This technique is fundamental in goldsmithing, allowing artisans to create pieces that are both beautiful and durable, turning raw metal into timeless, high-quality jewelry.

Please click on Additional information to find a list of needed tools and further information on this tutorial.